eddy currents and hardness testing for evaluation of steel decarburizing|Eddy currents and hardness testing for evaluation of : agencies Fig. 1. General synopsis of the experimental apparatus (Alphatest OMEGA 2000). - "Eddy currents and hardness testing for evaluation of steel decarburizing"

WEBDamas Jewellery Coupons . 32 Damas Jewellery Coupon Codes & Offers available . Founded in 1907, Damas is a Parisian jewellery brand offering jewellery pieces for men, women, and kids.

{plog:ftitle_list}

apostacerta. SEJA NOSSO PARCEIRO * Torne-se um Afiliad.

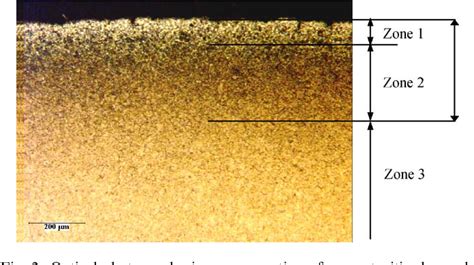

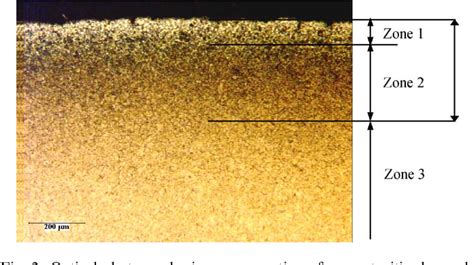

Until today, the eddy current technique is used to detect superficial defects. In practice, the control consists to create two groups of available samples or not, from a large . This paper presents an eddy current testing (ECT) method with a different type of referencing technique for crack detection in carbon steel plate by using two Anisotropic . Comparative study of eddy current and Barkhausen noise methods in microstructural assessment of heat treated steel parts. The present paper describes details . To characterize the extent of decarburizing phenomenon, observations by optical microscopy and/or hardness profiles measurements must be performed in a cross section, as .

How does the use of eddy currents impact the uniformity and efficiency of heat treatment for PHS steel? - Eddy currents used to assess decarburizing extent after heat .

Fig. 1. General synopsis of the experimental apparatus (Alphatest OMEGA 2000). - "Eddy currents and hardness testing for evaluation of steel decarburizing" Then we propose here to use eddy current testing, which is widely employed to detect fatigue cracks, to give some information about changes in microstructure and to examine carburizing of.To characterize the extent of decarburizing phenomenon, observations by optical microscopy and/or hardness profiles measurements must be performed in a cross section, as it is advised .

This study proposes eddy current testing (ECT) as a tool for nondestructive material characterization. In the present study, different dual phase steels (DPSs) with different .

In industrial case hardening, the temporal and local non-destructive characterization of occurring microstructural constituents creates new possibilities for automating manufacturing processes showing a high level of process reliability. Furthermore, component properties within the scope of quality assurance and product liability can be fully documented. .We will show, in the continuation, how eddy currents control is used to assess the level of decarburizing after a Fourier transformation performed on the output signal. This analysis allows us to link the harmonic decomposition of the signal to the duration of the heat treatment and/or to the total decarburizing depth and, consequently, to the . Steel industry has a strong interest to replace time consuming and expensive destructive mechanical tests by non-destructive methods, which can be even integrated in-situ within the production process. In the present work, the decarburization profiles in 51CrV4 steel have been investigated based on light microscopic inspection and hardness testing. NONDESTRUCTIVE DETERMINATION OF CASE DEPTH AND HARDNESS PROFILE BY THE INVESTIGATION OF THE PARTS RESPONSE TO THE INDUCTION CURRENT . 2012; The eddy current test is a non-destructive technique which can be performed rapidly. Since the eddy current response is . Eddy currents and hardness .

This last result has particularly motivated us to use eddy current to analyze decarburizing. In the present work, different durations in the furnace at a temperature of 920°C before oil quenching . 1. Introduction. Bearing is an important part of a machine which dramatically affects the performance, life and reliability of a machine [1], [2].Unqualified bearing rings may occur in terms of hardness at the manufacturing stage due to the imperfect heat treatment [3].For quality control of bearing rings, hardness testing after heat treatment is of great significance.Then we propose here to use eddy current testing, which is widely employed to detect fatigue cracks, to give some information about changes in microstructure and to examine carburizing of steel from both mechanical and microstructural point of view. . Combined Micro-Hardness and Eddy Currents Applied to the Study of Steel Decarburizing. D . At the second step the steel bars were held in 900 °C for different period of times and the depth of decarburizing layers were measured using hardness testing. Finally, the non-destructive eddy current technique was used and the response of test samples to the induction current including primary and secondary voltages, normalized impedance .

Eddy currents and hardness testing for evaluation of steel decarburizing. NDT&E International 2006; 39: 652-660 [6] Donald J.Hagemair, Fundamentals of E ddy Current Testing , American Society for Nondestructive Testing; 1990 [7] Don E.Bray, Roderic K. Stanley. Nondestruc tive Evaluation: A Tool Design, Manufacturing and Service. CRC Press; 1997

Eddy currents and hardness testing for evaluation of steel

Eddy currents and hardness testing for evaluation of

[8] Mercier D, Lesage J, Decoopman X and Chicot D 2006 Eddy currents and hardness testing for evaluation of steel decarburizing NDT & E Int. 39 652–60. Crossref Google Scholar [9] Amiri M S and Kashefi M 2009 Application of eddy current nondestructive method for determination of surface carbon content in carburized steels NDT & E Int. 42 618–21

Eddy current testing has long been used as a technique for investigation of defects. . Eddy currents and hardness testing for evaluation of steel decarburizing. . This well-known phenomenon is .

We show that eddy current test may be used to qualify the level of decarburizing since, after a convenient Fourier transformation, three components of the amplitude of the signal are directly linked to the duration of the heat treatment. . {Combined Micro-Hardness and Eddy Currents Applied to the Study of Steel Decarburizing}, author={David .

Eddy currents and hardness testing for evaluation of steel decarburizing. 2006, NDT and E International. . This well-known phenomenon is called decarburizing. It can change microstructure to a large extent and, as a result, bring dramatic modifications of mechanical properties of steel, like decrease of fatigue lifetime. . Reduction of lift .

Using Vickers hardness as the surface hardness index of AISI 410 steel, the relationship between eddy current output signal, in terms of impedance and inductance, and sample surface hardness was . Eddy currents and hardness testing for evaluation of steel decarburizing NDT E Int. , 39 ( 8 ) ( 2006 ) , pp. 652 - 660 View PDF View article View in Scopus Google Scholar In the field of pulsed eddy current (PEC) testing, the lift-off effect can mix up the signal features used for surface hardness classification. Eddy currents and hardness testing for evaluation of steel decarburizing NDT E Int , 39 ( 2006 ) , pp. 652 - 660 , 10.1016/j.ndteint.2006.04.005 View PDF View article View in Scopus Google Scholar

For instance, assessments of decarburizing depth [2, 3], surface carbon content [4] and wear rate [5] have been investigated in steel parts. . Vol. 23, pp. 83-92. Mercier, D., Lesage, J., Decoopman, X., & Chicot, D. (2006). Eddy currents and hardness testing for evaluation of steel decarburizing. . Eddy current evaluation of cast irons for . The nondestructive test method (eddy current) was employed to study the effect of different heat . Combined Micro-Hardness and Eddy Currents Applied to the Study of Steel Decarburizing. D. Mercier D. Chicot. Materials Science, Engineering . Eddy currents and hardness testing for evaluation of steel decarburizing. D. Mercier J. Lesage X .

Compared with traditional destructive hardness testing methods, eddy current nondestructive testing can evaluate the hardness of heat-treated materials without destructive sampling and also has the advantages of short analysis time and high efficiency. . Decoopman X., Chicot D. Eddy currents and hardness testing for evaluation of steel .DOI: 10.1016/J.NDTEINT.2006.04.005 Corpus ID: 138318799; Eddy currents and hardness testing for evaluation of steel decarburizing @article{Mercier2006EddyCA, title={Eddy currents and hardness testing for evaluation of steel decarburizing}, author={David Mercier and Jacky Lesage and Xavier Decoopman and Didier Chicot}, journal={Ndt \& E International}, .We will show, in the continuation, how eddy currents control is used to assess the level of decarburizing after a Fourier transformation performed on the output signal. This analysis allows us to link the harmonic decomposition of the signal to the duration of the heat treatment and/or to the total decarburizing depth and, consequently, to the .

This article describes a pulsed eddy current testing (PECT)-based novel method utilizing deep learning for reliable nondestructive testing of bearing rings. The continuous wavelet transform (CWT) was used to combine the time-frequency information in the PECT signals, and the deep learning models were trained to predict hardness. Steel industry has a strong interest to replace time consuming and expensive destructive mechanical tests by non-destructive methods, which can be even integrated in-situ within the production process. In the present work, the decarburization profiles in 51CrV4 steel have been investigated based on light microscopic inspection and hardness testing.Combined Micro-Hardness and Eddy Currents Applied to the Study of Steel Decarburizing D. Mercier, D. Chicot. Laboratoire de Mécanique de Lille, LML UMR 8107, U.S.T. Lille, . Then we propose here to use eddy current testing, which is widely employed to detect fatigue cracks, to give some information about changes in microstructure and to .

Eddy currents and hardness testing for evaluation of steel decarburizing D. Mercier , J. Lesage, X. Decoopman, D. Chicot Laboratoire de Me´canique de Lille, LML UMR 8107, U.S.T. Lille, IUT A GMP, BP 179–59653 Villeneuve d’Ascq Cedex, France Received 3 February 2006; received in revised form 6 April 2006; accepted 10 April 2006 Eddy current testing has long been used as a technique for investigation of defects. However, determination of surface carbon content in carburized steels is a new application for this method which has been studied in this research. Sixteen AISI 4118 steel samples have been carburized in an enriched carbon gas carburizing furnace.

Combined Micro

Application of eddy current nondestructive method for

Resultado da 19 de jan. de 2024 · Os atletas Malcolm Gordon e Jimmy Flick fazer parte do primeiro confronto do card preliminar inicial do UFC 297, que acontece nesta noite de sábado (20) com previsão para começar às 20h30 (horário de Brasília).Ambos chegam com derrotas e formas de lutar muito diferentes. .

eddy currents and hardness testing for evaluation of steel decarburizing|Eddy currents and hardness testing for evaluation of